Innovation et tradition : le point de vue des PME françaises de la filière blé dur

- Type de publication : Article de revue

- Revue : Systèmes alimentaires / Food Systems

2018, n° 3. varia - Auteurs : Mandato (Sandra), Vries (Hugo de), Mayer-Laigle (Claire)

- Résumé : Ce travail vise à évaluer le potentiel des innovations issues de la recherche pour relancer la croissance des PME françaises de la filière blé dur. Les résultats mettent en évidence le double enjeu des PME de ce secteur pour rester compétitif : parvenir à innover en préservant le caractère traditionnel de leurs produits et leur savoir-faire. Ils montrent également l’importance d’actions concrètes telles des formations, des journaux spécialisés ou des plateformes technologiques de démonstration.

- Pages : 245 à 257

- Revue : Systèmes alimentaires

- Thème CLIL : 3306 -- SCIENCES ÉCONOMIQUES -- Économie de la mondialisation et du développement

- EAN : 9782406087229

- ISBN : 978-2-406-08722-9

- ISSN : 2555-0411

- DOI : 10.15122/isbn.978-2-406-08722-9.p.0245

- Éditeur : Classiques Garnier

- Mise en ligne : 10/12/2018

- Périodicité : Annuelle

- Langue : Anglais

- Mots-clés : Produit alimentaire traditionnel, PME, innovation, filière blé dur, transfert de connaissances

Innovation and tradition:

The viewpoint of French SMEs

in the durum wheat sector

Sandra Mandato, Hugo de Vries & Claire Mayer-Laigle

UMR 1208 IATE, Cirad, Inra, Montpellier SupAgro,

University of Montpellier

Introduction

Numerous food-related agricultural, technological, product-related, marketing, and business innovations have been developed by research institutes, universities and technical centers around the world (Bimbenet et al., 2007; Roos et al., 2015; Gormley, 2015). Such innovations could be adopted by small and medium-sized enterprises (SMEs), the majority of stakeholders in the agri-food sector (Spillan & Parnell, 2006), particularly in the traditional food sector. However, many innovations, especially technological ones, do not reach all SMEs despite the fact traditional food SMEs have a high potential for innovation, as recognized by the Small Business Act for Europe adopted in June 2008 (Commission of the European Communities, 2008).

In the durum wheat sector, traditional food products and traditional production methods are widely used by SMEs, but these firms face hard competition from multinationals. Today, the many challenges with which SMEs have to cope include changing consumer preferences and retail demand, changing government regulations, competing high quality added value food products, economies of scale and environmental 246restrictions, using limited resources compared with those available to big firms. The ‘traditional versus modern’ competition could lead to the disappearance of traditional recipes and practices, thus justifying the need to develop strategies to maintain cultural and culinary heritages. Innovations could contribute to this aim by (1) providing an attractive range of traditional products that takes consumer expectations into account, (2) increasing the competitiveness and economic profits of traditional food producers, and (3) making sustainable development a business reality.

The European TRAFOON project (Traditional Food Network to improve the transfer of knowledge for innovation) started in November 2013 with the aim of supporting SMEs that produce traditional food by establishing a knowledge and innovation transfer network with a focus on food products made of grains, fish, fruit, vegetables and mushrooms. In this project, a traditional food is defined as a “Food which is produced according the gastronomic heritage by at least three generations, which shows specific feature(s) that distinguish it clearly from other similar products of the same category in terms of the use of ‘traditional ingredients’ (raw materials of primary products) or ‘traditional composition’ or ‘traditional type of production and/or processing method´. Furthermore it is associated with a certain local area, region or country”.

Here, we gathered information on the innovation and training needs of SMEs throughout the value chain, and matched them with recent innovations and current research topics in order to understand the nature and usability of potential innovations in the traditional food sector.

1. Materials et Methods

1.1. The durum wheat sector in France

The French durum wheat sector is organized in an upstream and downstream value chain. The upstream chain covers several steps from seed production to the collection of durum wheat grains. The upstream part of the durum wheat sector includes grain producers (mainly SMEs), and less than 20 collectors (Fares et al., 2012). The downstream chain 247generally starts with the first transformation of durum wheat into semolina followed by the second transformation to obtain pasta, couscous and other end products. The three major manufacturers of dry pasta (Panzani, Pastacorp, Alpina Savoie) include semolina milling. Three SMEs (Thirion, Heimburger, Valfleuri) are specialized in the manufacture of traditional Alsatian dry pasta but each account for less than 5 % of the total market share (Fares et al., 2012). In addition to these firms, there are a few small-sized dry pasta manufacturers and a large number of micro-sized firms, each accounting for less than 1 % of the market share (Fares et al., 2012). Small-sized fresh pasta makers also exist, along with many micro-sized firms. About 90 000 tons of couscous are manufactured every year by the first three dry pasta makers and one other large firm (Tipiak). It is likely that some micro-sized enterprises prepare bulgur or couscous at artisanal scale, but at relatively small production volumes compared to the total volume produced in France. Although other companies producing pasta, couscous, bulgur, etc. produce traditional products according to the TRAFOON definition, only the SME(s) are targeted in this study (less than 250 employees, sales below 50 million euros or an annual balance sheet below 43 million euros) .

1.2. Methodology of the study

Major research topics and innovations in durum wheat sectors were identified by collecting information from current and past research projects and literature reviews, and by conducting 15 interviews with experts, eight of them were from the academic world and seven professionals (SME associations, technology transfer agencies, etc.). These interviews have also helped to identify the opportunities and threats for the French SMEs. Next, a survey was conducted to identify SME needs. Two questionnaires were used. The first was qualitative, based on semi-structured face-to-face or telephone interviews, and aimed to identify major problems facing the SMEs. The second questionnaire (accessible online) was quantitative and made it possible to identify the business direction of SMEs and their own perception of their innovative potential. In addition, SME directors were asked to rate their interest in five categories (agronomic, technological, product-related, marketing, and organizational) of current research topics and innovations and in training topics by attributing a score from 1 (limited interest) to 5 (strong 248interest). Thanks to open-ended questions, respondents were encouraged to provide additional suggestions. 19 SMEs have been interviewed and 12 have entirely completed the questionnaires. Partially completed questionnaires have been exploited as well for providing additional information. The results of both questionnaires are discussed below in relation to the expert opinion gathered in the first part of the study.

1.3. SME interviewed profile

A total of 487 SMEs in the whole durum wheat sector were identified in the DIANE database. Most were restaurants and/or caterers, which were not included in the panel targeting SMEs in either the upstream and downstream durum wheat sector. In the end, 30 SMEs selling traditional products according to the definition given in introduction were contacted and 19 agreed to be interviewed, nine were pasta makers, seven were grain producers and pasta makers, two cooperatives, and one a miller; these figures are highly representative of SMEs in the French durum wheat sector. The average number of full time equivalent employees was 4.8, the maximum 17 and some micro-enterprises were run by only one person. Thus, the results present below concerns rather small firms than medium sized enterprises.

The turnover of 23 % of the firms ranged from 1000k€ to 5000k€, 15 % between 500k€ - 1000k€, 46 % between 100k€ - 500 k€ and 16 % between 50k€ - 100k€. 41 % of the SMEs surveyed sold their products in local and/or regional markets. Only 23 % of the SMEs said they sold their products on national markets and 9 % on the international market. One third of SMEs interviewed sold only conventional products. Two thirds sold organic products from which three-quarters of them sold only organic products.

2492. Results and discussion

2.1. The innovative potential of French SME s

in the durum wheat sector

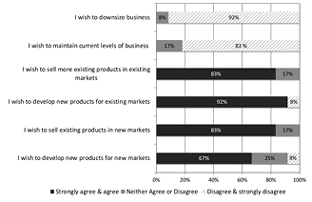

All the enterprises interviewed, except one, considered their food products to be traditional, based on the definition of a ‘Traditional Food’ given in the TRAFOON PROJECT. They are convinced that innovation and tradition are compatible and necessary, at least in their sector of activity. The only firm that did not consider its products traditional, believed tradition and innovation are incompatible, as the innovative aspect of its products is not compatible with the notion of tradition. The SMEs interviewed appeared to be dynamic, willing to innovate and invest with mature facilities in the case of almost half. They wanted to increase their market share by selling new products in existing markets; two thirds envisaged entering new markets (Fig. 1).

Fig. 1 – Business directions resulting from the questionnaire.

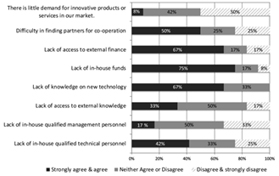

250However, the main barriers to innovation and business development appeared to be financial with either lack of access to external investment or in-house funds (Fig. 2) as is also the case of SMEs in other countries across all manufacturing sectors (Madrid-Guijarro et al., 2009; Zhu et al., 2012). The lack of knowledge about new technology and the difficulty to find partners for co-operation appear also as hurdles to development. Thus, enhancing and facilitating SMEs networks as well as fostering contact between SMEs and researchers could thus help SMEs to increase their knowledge on technologies and identify new partners as also suggested by Santoro & Gopalakrishnan (2000) and Bruneel et al. (2010). On the other hand, the lack of in-house management and technical qualified personnel divided the respondents and appeared to depend on the enterprise (Fig. 2).

Fig. 2 – Innovation barriers as perceived by the respondent.

2.2. SME training and innovation needs

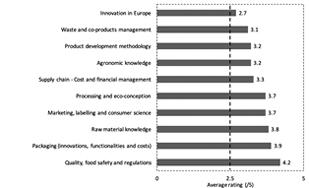

SMEs in the durum wheat sector were quite interested in training, as all the scores of the training topics were above 2.7/5 (Fig. 3). Training in quality, regulation and consumer science were the most in demand. Better knowledge of raw materials and transformation processes were also seen as key preoccupations.

251

Fig. 3 – Rating of training subjects by the respondents.

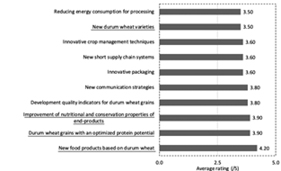

SMEs were also asked to rate 20 different innovations from current and past research projects. Ten of them obtained a score above 3.5/5.

Figure 4 presents the highest rated innovations (i.e. average score above 3.5/5).

Fig. 4 – Highest rated innovations related

to durum wheat (i.e. average score above 3.5/5).

The 4 product-related innovations (underlined in Fig. 4) are all among the highest rated innovations with particular interest in new food products based on durum wheat. It should be noted that most of the highest rated expected innovations (e.g. “Durum wheat grains with an optimized protein potential”, “Development of quality indicators of durum wheat grains” and “Innovative crop management techniques”) are currently under study in R&D projects. One example is the DurDur project (2014-2017, ANR-13-ALID-0002) whose aim is to design sustainable technological itineraries for the production and processing of durum wheat grains in order to control the protein content and the level of contaminants in both the grains and derived products. As mentioned above, the respondents want marketing innovations, new communication strategies. Technological innovations appear to be less in demand. “Reducing energy consumption by processing equipment” was ranked 10th (3.5/5). The application of eco-conception concepts during processing does not appear to particularly interest SMEs in the durum wheat sector. This is even more striking since a recent report by the European commission showed that the global energy consumption by the cereal sector is one of the highest compared to other food sectors, for example, the fruit and vegetable sector (JRC Science and policy report, 2015). However, energy consumption varies significantly in the different stages of the supply chain; the perception of energy consumption is probably related to the role played by the SME concerned in the chain.

Other technological innovations suggested, such as precision farming, new fractionation processes and concept of agro-technological parks were the lowest-rated innovations. These results are rather surprising in light of the research efforts invested in these areas in the past few years and show that, at least in the early stages, these innovations benefit bigger companies more than SMEs.

2533. Opportunities for and threats

to French SMEs in the durum wheat sector

In the opinion paragraph below, the authors give their view on opportunities and threats for French SMEs in the durum wheat sector; this is based on results of the quantitative study and expert opinions gathered during interviews.

Most of the SMEs interviewed used organic practices, but the French organic durum wheat sector suffers from the lack of a certified durum wheat variety that complies with organic farming regulations; hence, durum wheat processors have difficulty securing a supply of organic durum wheat grains and/or semolina and the temptation is strong to buy semolina from producers in foreign countries whose prices are highly competitive. Today, upstream-downstream relations and contractualization are the subject of research in France, notably in relation with the agro-ecological transition and the cultivation of mixed crops (Fares et al., 2012). However, at the time of writing, re-structuring concepts are awaited by several stakeholders in the durum wheat sector. Moreover, in France, the recent emergence of durum wheat grain producers who diversify their activities by processing their wheat into pasta on the farm, is evidence for the innovation potential of small-scale producers. By occupying a niche market, these producers exploit their grain production better, eliminating risks linked to price fluctuations and matching French consumers’ relatively high demand for artisanal and traditional food products. Nevertheless, the launching of new products on the durum wheat market, changing legislation, recruiting and keeping qualified personnel, etc. requires tailored training and the creation of a technical demonstration center for the processing of durum-wheat based products (as we have noticed for French canned goods).

The downstream part of the French durum wheat sector lacks monitoring tools and control of processes. This is in particularly true for the smallest SMEs that mainly rely on their artisanal know-how and empirical skills to adapt to natural variations in the characteristics of the raw material, the impact of climate change, etc. Small-scale businesses in the durum wheat sector suffer from lack of scientific knowledge, notably 254on managing processing (e.g. the pasta drying process). The directors of SMEs in the durum wheat sector expressed their reservations towards novel and emerging technologies, mainly because of the associated costs (the need for expensive equipment and the cost of maintenance) and in the case of organic products, due to the different restrictions imposed by the regulations and uncertainties concerning possible consumer perception of novel technologies. Our interviews with the SMEs revealed that the use of cutting-edge technologies (either perceived as “very” or “too” innovative) is often perceived as inappropriate for artisanal and traditional production. In this sector, product innovation is guided by the desire to produce “something different”, to “change the routine” and by consumer feedback. Research and development activities are rarely formalized and frequently originate from ideas that emerge from a closed circle of stakeholders. Moreover, it appears that some niche markets are still not fully exploited (mixed legume-durum wheat products, old varieties, flavored products, whole grains, etc.) or need to be reconsidered (sprouted wheat, sweet or fermented durum wheat-based products, beverages, etc.).

Generally, the SMEs we interviewed intend to create added value by differentiation based on taste, product origin, nutritional composition, type of processing, using for example, artisan methods as oppose to “ultra-processing”, as defined by Monteiro et al. (2013), and the use of old varieties as raw materials. Due to limited human and financial resources, only some small businesses integrate new media in their communication and marketing strategies, and are therefore relatively ‘low-tech’ but at least they exist (with a web site and sometimes a Facebook page).

On the other hand, SMEs benefit from several assets including high flexibility and reactivity thanks to their ability to produce small and medium amounts of products thereby enabling them to rapidly adapt to the market to win some specific contracts and to launch product innovations at lower risk. In addition, the consumption of food products based on durum wheat is promoted by the Mediterranean diet guidelines and the French national food-related campaigns (e.g. the “National dietary and health plan”, Plan National Nutrition Santé and the “National program for food”, Programme National pour l’Alimentation), which could enhance the competitiveness of small-scale enterprises. Changes in eating patterns towards origin-linked and healthy food products, appropriate small-scale production schemes as well as recent and future research 255advances in packaging, the management of processing, and improved production methods appear to be real opportunities for SMEs.

Conclusion

The aim of this study was to identify the innovation and training needs of SMEs producing traditional durum wheat based products via questionnaires and in-depth interviews. The SMEs were found to have limited ability to either carry out – or be involved in – medium and long-term research and development strategies due to lack of time and resources. Their innovation needs are not always directly linked to current research questions, notably in the technological domain, whereas research often focuses on the interests of large enterprises. Nonetheless, the SMEs we interviewed turned out to be extremely dynamic and innovative-minded especially concerning new products, processes, distribution channels and markets. At artisanal and semi-industrial scales, the main challenge is to innovate without losing the traditional image of their products especially given local and regional consumer perception and demand. Although limited by their financial and human resources, the SMEs interviewed showed keen interest in recent research innovations including mixed crop-based products, bio-based and functional packaging, and eco-conception, especially during processing.

The high ratings given to the training topics underlines the need for an action plan for dedicated professional training for SMEs in the traditional food sector. Key training courses are required in food legislation, packaging and quality maintenance as well as in waste reduction and valorization, marketing and labelling, sustainable processing and knowledge of the diversity and quality of agro-resources. In addition to the direct feedback of SMEs, we think that the use of online portals, a new traditional food-oriented magazine specifically designed for SMEs, and a joint technology demonstration platform with easy access to pilote scale facilities and exchange with researchers and innovators, speaking the language of SMEs, could provide valuable assets for innovation and competitiveness of SMEs .

256Discussions with SME and experts revealed that it is actually quite difficult to agree on a clear and precise definition of a traditional food product. Can a product still be considered traditional if only the ingredients are changed but not the manufacturing process? How to agree on a general and objective rule? How ‘Traditional Food’ is defined is still a tricky question, a satisfactory definition and protection at a national legislative level is still lacking, notably in European countries.

257References

Bimbenet J.-J., Schubert H., Trystram G., 2007, “Advances in research in food process engineering”, Journal of Food Engineering, vol. 78 ,p. 390-404.

Bruneel J., D´Este P., Salter A., 2010, “Investigating the factors diminishing the barriers to university-industry collaboration”, Research Policy, vol. 39, p. 858-868.

Commission of the European communities, 2008, “Think small first: a Small Business Act for Europe”.

Fares M., Magrini M.B., Triboulet P., 2012, “Transition agro-écologique, innovation et effets de verrouillage: le rôle de la structure organisationnelle des filières. Le cas de la filière blé dur française”. Cahiers Agriculture, vol. 21, no 1, p. 34-45.

JRC Science and policy Report, 2015, “Energy use in the EU food sectors: state of play and opportunities for improvement”.

Gormley R., 2015, “Food Science Research and Innovation: Delivering sustainable solutions to the global economy and society: Outcomes from the EFFoST Annual Meeting 2015, Athens, Greece”, Trends in Food Science & Technology, vol. 50, p. 254-261.

Madrid-Guijarro A., Garcia D., Van Auken H., 2009, “Barriers to innovation among Spanish manufacturing SMEs”, Journal of Small Business Management, vol. 47, no 4, p. 465-488.

Monteiro C.A., Moubarac J.-C., Cannon G., Ng W., Popkin B., 2013, “Ultra-processed products are becoming dominant in the global food system”, Obesity Reviews, vol. 14, no 2, p. 21-28.

Roos Y. H., Fryer J. P., Knorr D., Schuchmann H. P., Schroën K., Schutyser M. A. I., Trystram G., Windhab E. J., 2015, “Food engineering at multiple scales: case studies, challenges and the future – A European perspective.”, Food Engineering Reviews, vol. 8, no 2, p. 91-115.

Santoro M.D., Gopalakrishnan S., 2000, “The institutionalization of knowledge transfer activities within industry-university collaborative ventures”, Journal of Engineering and Technology Management, vol. 17, p. 299-319.

Spillan J., Parnell J., 2006, “Marketing resources and firm performance among SMEs”, European Management Journal, vol. 24, p. 236-245.

Zhu Gormley Y., Wittmann X., Peng M. W., 2012, “Institution-based barriers to innovation in SMEs in China”, Asia Pacific Journal of Management, vol. 29, p. 1131-1142.